I-HZ-S0206

Imingcele yesakhiwo

Imingcele eyisisekelo

| Imodeli | I-HZ-S0206 |

|

Izinga lokushisa lombala/umbala | 2300K |

| 2700K | |

| 3000K | |

| 4000K | |

| 6000K | |

| Umugqa wokukhanya ofanayo | 2216-240-24V-3mm |

| CRI | >90 |

| I-Voltage (V) | 24 |

| Ugesi wamanje (A) | 0.48 |

| Amandla (W/m) | 5 |

| lm/ubude begagasi | 107 |

| 108 | |

| 113 | |

| 126 | |

| 130 | |

| Usayizi (mm) | 2.5×6 |

| Ubude obujwayelekile | 5000mm |

| Iyunithi yokugunda (mm) | 25 |

| Izilinganiso ze-IP | IP67 |

Indlela yokufaka izintambo

Imingcele yemishini

Ipulaki yeglue

Inqubo yokukhiqiza

Ukuthengwa Kwempahla Engavuthiwe

1.Ukukhethwa kweChip: Ngokwezidingo zokusebenza zokukhanya, izinga lokushisa lombala, inkomba yokunikeza umbala nezinye izakhiwo ekwakhiweni komkhiqizo, ama-chips ekhwalithi ephezulu we-SMD LED athengwa kubahlinzeki abathembekile. Lawa ma-chips kufanele ahlolwe ngokuqinile ngamasampula ngaphambi kokuthengwa ukuze kuqinisekiswe ukuthi izakhiwo zikagesi nezamehlo ziyahlangabezana namazinga.

2.Ukuthengwa Kwempahla Yebhodi Lesifunda: Khetha ibhodi le-FPCB lekhwalithi ephezulu elifanele, ulinganise ukumelana kwayo kwezinga lokushisa, ukuqhutshwa kwayo kanye nokuguquguquka, futhi uthenge izingxenye ezihlukahlukene ze-elekthronikhi ezidingekayo ekukhiqizeni ngesikhathi esifanayo, njengama-capacitor nama-resistors, konke okumele kuhlangabezane nezindinganiso zekhwalithi ezimisiwe.

3.Ukuthengwa Kwempahla Ewusizo: Thenga izinto ezisizayo ezifana nokunamathiswa okungu-3M kokuhlanganiswa kwe-strip, i-solder paste yokushisela kanye neglue ukuze i-encapsulation nokuvikela, futhi uqinisekise ukuthi i-viscosity yabo, ukuqina nezinye izici zihambisana nenqubo yokukhiqiza i-strip.

Inqubo yokuchibiyela

1.Solder Namathisela Ukuphrinta: I-solder paste iboshwe ngokunembile ezindaweni zephedi zebhodi lesifunda le-FPCB. Ngokusebenzisa umshini wokuphrinta wokunamathisela we-solder onembile kakhulu futhi ngokusho kwesifanekiso esisethiwe, ukujiya nokuma kwe-solder paste kuqinisekiswa ukuthi kufana futhi kunembile, kubeka isisekelo esihle sokunamathisela ubuhlalu okulandelayo.

2.Ukupheca ubuhlalu: Ngosizo lomshini wokubeka othomathikhi, ubuhlalu obuthengiwe be-SMD LED buxhunywe ngokushesha futhi ngokunembile kumaphedi aphrintiwe nge-solder paste ngokusho kwesakhiwo sokuklama. Inqubo yokuchibiyela igadwa uhlelo lokubona komshini kuyo yonke inqubo, futhi ukuchezuka okuncane kungalungiswa ngesikhathi.

Ukuhlola okubonakalayo

Yenza ukuhlola okubonakalayo okwenziwa ngesandla kumugqa we-LED obekwe phezulu.

I-Reflow Soldering

1.Isilungiselelo sepharamitha: Ngokwezici zokunamathisela kwe-solder esetshenzisiwe kanye nokucaciswa kobuhlalu, lungisa ngokucophelela imingcele yendawo ngayinye yokushisa emshinini wokushisa we-reflow, okufaka ukushisa okushisa, izinga lokushisa, izinga lokushisa lokugeleza kabusha kanye nezinga lokupholisa. Ukusetha okunembile kwepharamitha kuyisihluthulelo sekhwalithi yokushisela.

2.Welding Ukubulawa: Beka ibhodi lesifunda elinezichibiyelo ebhandeni elihambisayo lomshini we-reflow soldering. Njengoba ibhodi lesifunda lidlula ezindaweni zokushisa, ukugeleza kabusha kanye nokupholisa ngokushintshana, i-solder paste iyashiswa ukuze incibilike futhi iqinise, iqaphela uxhumano oluqinile lukagesi phakathi kobuhlalu kanye nebhodi lesifunda. Ngalesi sikhathi, opharetha unaka kakhulu isimo sokusebenza semishini.

Ukuhlola Nokulungisa

1.Ukuhlola Okubonwayo: Yenza ukuhlola kokuqala okubonakalayo komugqa oshiselwe ukuze uhlole ukuthi akukho yini ukusoda okubonakalayo, ukusoda okulahlekile, ukusoda ngokuqhubekayo kobuhlalu, ukuthi ubuhlalu bulimele noma bususiwe, nokuthi ingabe kukhona ukuklwebheka noma okunye ukonakala ebhodini lesifunda. .

2.Ukuhlola Amandla: Xhuma umugqa endaweni yamandla kagesi engu-24V efanelekile, bheka isimo sokukhanya sobuhlalu, hlola ukuthi ukukhanya kuyafana, kukhona ukukhanya kwe-stroboscopic nokuthi izinga lokushisa lombala lijwayelekile yini. Maka imikhiqizo enesici futhi uhlele izisebenzi zokunakekela eziqeqeshiwe ukuze ziyilungise.

I-Neon Extrusion

1.Izinto Zokuxutshwa Nokucutshungulwa: Engeza izinto zokusetshenziswa eziqinile ze-silicone nezithasiselo ezifana nama-ejenti abangela ukushisa kumxube ngesilinganiso esithile bese ugoqa futhi uphendule kuze kube yilapho i-silicone eqinile isifana ngokuphelele. Kwezinye izidingo ezikhethekile zamapheshana akhanyayo, kungase kudingeke ukwengeza i-masterbatch yombala nezinye izinto ukuze ulungise umbala.

2.FPCB Flexible Board Processing:Ibhodi eliguquguqukayo le-FPCB elinobuhlalu be-LED obufakiwe kanye nokuphothulwa kokuthelwa kabusha kwe-reflow soldering ingaphansi kokwelashwa kokushaqeka kokuguga ukuze kuhlolwe ukuzinza nokuthembeka kwayo. Ngemuva kokushaqeka kokuguga, lonke ibhodi eliguquguqukayo le-FPCB libekwa ebhentshini lokusebenza elimbozwe ngesikhumba esiqinile ukuze kuhlukaniswe ibhodi futhi lihlukaniswe ngemicu eyodwa ye-FPC eguquguqukayo. Futhi ukukhanya kobuhlalu be-LED ngayinye buyahlolwa, futhi abafanelekayo bayahlanganiswa.

3.I-Extrusion: Hlukanisa i-silicone eqinile enyakaziswayo futhi efanayo njengoba kudingekile, bese uthumela umugqa oguquguqukayo we-FPC ku-extruder efakwe ukufa kwe-extrusion, bese uthumela i-silicone eqinile ehlukanisiwe. Ngesikhathi esifanayo, vula ihhavini lokubhaka kanye ne-extruder bese uqala i-extrusion nokubhaka ukwelapha. Phakathi nenqubo yokukhishwa, i-silicone eyenziwe ngepulasitiki iyancibilika ngaphansi kokuzungezisa isikulufu futhi idlule ku-die of extruder. Isikulufu kanye nokufa kwe-extruder kusebenzisa ingcindezi ekuncibilikeni ukuze kuyikhiphe kumkhono noma igobolondo lomugqa wokukhanya we-neon ngokuya ngomumo nosayizi wedayizi bese usonga ibhodi le-FPC eliguquguqukayo kulo.

Ukupholisa nokuBunjwa

1.Ukupholisa: Umugqa wokukhanya we-neon okhishiwe ungena ngokushesha kudivayisi yokupholisa, njengethangi lamanzi okupholisa noma idivayisi yokupholisa umoya, ukuze i-silicone iphole ngokushesha futhi iqinise futhi igcine umumo nosayizi ngesikhathi sokukhipha.

2.Ukubunjwa:I-neon light strip ngemva kokupholisa inobunzima obuthile kanye nokuzinza komumo futhi ingacutshungulwa futhi ilashwe ngokulandelayo.

Ukucubungula Okulandelayo

1.Ukusika nokunquma: Sika futhi usike umugqa wokukhanya we-neon okhishiwe ngokobude obudingekayo. Ngokuvamile, amathuluzi okusika noma amathuluzi okusika azosetshenziswa ukusika umugqa wokukhanya ube ubude obujwayelekile.

2.Ukuhlola nokuhlola: Yenza ukuhlola ukubukeka, ukuhlola amandla okukhanya, njll. emgqeni wokukhanya we-neon ngobuhlalu obukhanyayo obufakiwe ukuze uhlole ukuthi ingabe isimo sokukhishwa kokukhanya, ukufana kombala, ukusebenza kukagesi, njll. kobuhlalu bokukhanya kuyahlangabezana nezimfuneko futhi kususe imikhiqizo enesici.

Ukuhlanganisa kanye Nokupakishwa

1.Umhlangano Wezesekeli: Namathisela okunamathelayo okungu-3M emgqeni oqeqeshiwe ohloliwe ukuze kube lula ukufakwa okulandelayo. Ukuze uthole amapheshana angangeni manzi, ukwelashwa okungeziwe kokuvala kuzokwenziwa, futhi imikhono engenamanzi, ama-gaskets enjoloba nezinye izingxenye zizongezwa.

2.Ukupakisha kanye nokugcinwa kwempahla: Faka umoya bese upakisha imichilo ngendlela ehlelekile ngokuhambisana nobude obujwayelekile, obufana no-5000mm umqulu ngamunye, faka ifilimu yepulasitiki nebhokisi lebhokisi, unamathisele ilebula yomkhiqizo, ekhombisa imininingwane, imodeli, usuku lokukhiqiza nolunye ulwazi, bese uhambisa. ziyiswe endaweni yokugcina izimpahla, zilinde ukuthunyelwa.

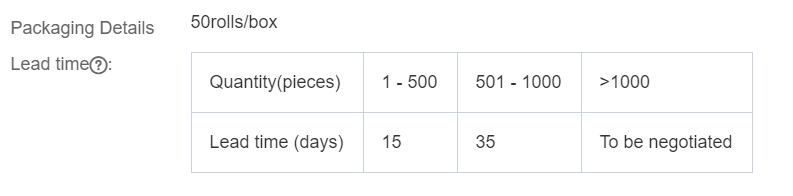

Ukupakisha nokulethwa

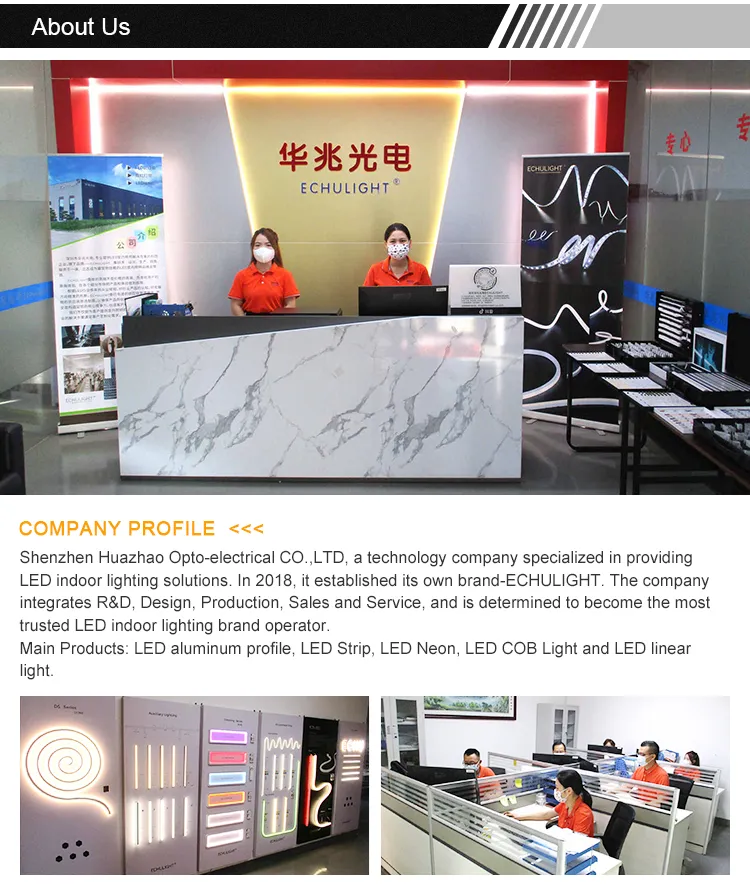

Mayelana NATHI

Imboni Yethu

Izinzuzo Zethu

Isitifiketi

Ukuthumela Nokukhokha

FAQ

OkuhlobeneIMIKHIQIZO

-

Ucingo

-

I-imeyili

-

Phezulu